Everything is connected. This first Law of Ecology “reflects the existence of the elaborate network of interconnections in the ecosphere: among different living organisms, and between populations, species, and individual organisms and their physicochemical surroundings.”

Similar to our ecosystem, small changes ripple across companies and organizations with unintended consequences. Decisions on solutions and the parties involved in your Lean project teams can have long-reaching implications that may not be understood initially.

Let me give you a glimpse into the world of complexity.

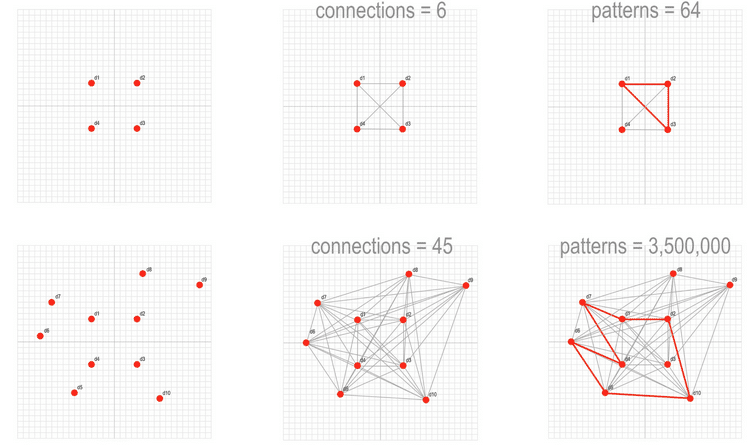

Imagine that you have four decisions to make. You can connect them in six ways and arrange them in 64 patterns. Now, think of ten decisions your team has to make. You can connect those ten decisions in 45 possible ways, but you can arrange them in over 3,500,000 possible patterns! If the sequence of decisions has meaning, that small change in quantity has huge implications in possible outcomes.

Complex or complicated?

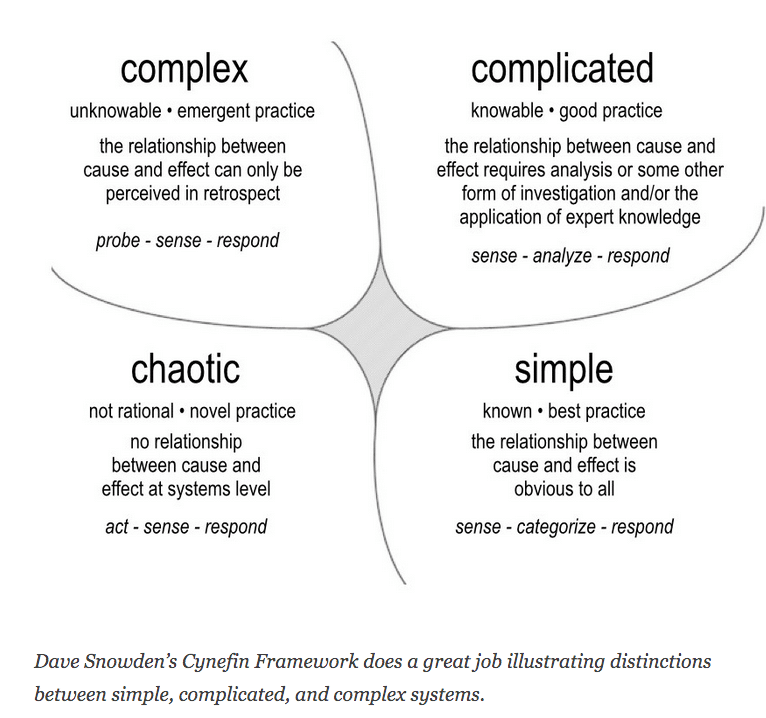

Complexity is different than complicatedness, and greatly different than simplicity. Consider:

There was a point in time where our projects were relatively simple in terms of the number and type of decisions we had to make. Especially in the AEC (Architecture, Engineering, Construction) space, our materials were limited, structural systems not very sophisticated, mechanical and electrical systems non-existent, etc. As a result, projects were pretty easy to manage: we knew what we knew and also knew what we didn’t know, swiftly resolving conflicts and problems by making an appropriately arranged series of decisions. Let’s call this the age of simple systems, where things were known: the relationship between cause and effect was obvious to all. Decisions had expected outcomes. We could manage work with techniques like a simple checklist.

Over time, our projects increased in complexity. We started to employ a broader range of materials, better understanding their interactions; structural systems became more sophisticated, simple mechanical and electrical systems were introduced. Projects were more challenging to manage: we knew what we knew, and through analysis, could discover and know what we didn’t know, responding accordingly. An era of complicated systems where the relationship between cause and effect required analysis or some other form of investigation and/or the application of expert knowledge. We made decisions layered on decisions, but we got to where we wanted to go, predictably. We typically used Gantt charts or the Critical path method to manage and control our projects.

30% of projects are behind schedule and over budget

Next, our projects swiftly transitioned into complexity. Again looking at the AEC space, the range of material choices expanded exponentially, as did the possible interactions between them. Structures became increasingly difficult to analyze, especially as our knowledge of seismic and other less predictable forces grew. Mechanical, electrical, plumbing, security, acoustical, these systems utilize hundreds of parts, with decisions about one part of one system having impact on other parts of other systems, which in turn affected other parts of other systems, and so on. Experts emerged as specialists in each of these systems, with boundaries of responsibility drawn between them. Decisions in one area then could easily ripple across a boundary and have a significant impact on someone else’s area of responsibility. We have long tried to manage today’s work using tools suited for complicated work, but we fail on a regular basis: industry research tells us at least 30% of projects are behind schedule and over budget.

So what are characteristics of complex systems?

Complex systems simply have many moving parts with connections between those parts, some known, some unknown. Small changes in a complex system can ripple across both understood and less understood connections and create outcomes and changes that were completely unexpected. Our actions are part of the complex system: simply by interacting with a complex system we can change its dynamic and ultimately its effectiveness. We can poke the system and observe its reaction, and then manage toward desired outcomes, but complex systems are inherently resistant to tight-fisted control.

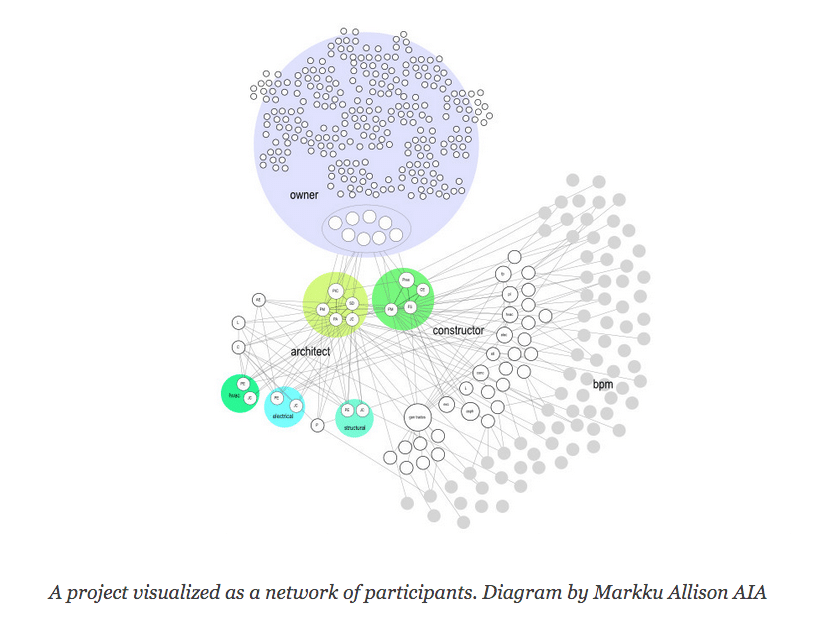

Why does any of this matter? Projects in LeanIPD are ultimately about decisions: all completed projects are records of a series of decisions made over time. Most projects require hundreds or thousands of decisions, and they are usually made by not one but by many people, sometimes in concert but many times not. If my decision has an impact on your decisions, which is almost always the case, and we don’t make those impacts explicit and visible, we are likely to run into unexpected outcomes. Herein lies the challenge, and the opportunity.

Are you treating symptoms or causes?

Complexity is pervasive in today’s workplace, but our understanding of it is not. Think of the structure of your organization, or of a recent project you worked on. Think of one major decision. Think of the supporting decisions that led to that decision, and the decisions that will flow from it now that it’s made. Draw a diagram of all the individuals who contributed to the decision, its supporting decisions, or ones to follow, and how they are connected to one another. Layer on groupings like departments, trades, disciplines, or teams, and consider the additional impact on decisions from that angle.

Where are the lines of responsibility?

Where are the boundaries between my job/decision and your job/decision?

It will quickly become a spaghetti diagram with no clear logic or flow, yet somehow we muddle through, and work gets done. It just doesn't usually happen in the way we thought it would.

A deep current of complexity manifests in the workplace as extended schedules and missed deadlines, unmet expectations, blown budgets, dropped balls, mixed, missing, or garbled messages, work that is redundant or at cross purposes. The list goes on. A list of symptoms, not causes.

Change your perspective

However, if we take steps to make the complexity inherent in our organizations and projects explicit, we can start to see how we might address these kinds of problems. We can introduce ways of thinking about teams as networks. We can use tools and methodologies, such as value stream mapping, design structure matrices, or visual management techniques, that make connections between decisions and decision-makers visual and visible. These steps may seem simple on the surface but when effectively deployed in a workplace can have a profound impact on the organization’s ability to see a bigger picture and make informed decisions in our projects.

How to deal with complex challenges

But simply exposing complexity isn’t enough. Dealing with complex challenges requires a whole new approach. We already know from experience that tools that worked for complicated problems aren’t flexible or agile enough for complex problem solving. Neither are cultures rooted in those tools and techniques, which is to say most cultures.

Further reading on how you can change your team culture:

How to Empower your Lean Project Teams for Success, Part 1

How to Empower your Lean Project Teams for Success, Part 2

How to Empower your Lean Project Teams for Success, Part 3

Subscribe to the LeanIPD newsletter to get monthly updates from leading experts in the Lean industry.

Markku Allison, AIA, has over 35 years of experience both as an award-winning designer and as a thought-leader on design and construction industry transformation issues. His background as a practice owner and industry subject matter expert with strong relationships across disciplines and organizations uniquely positions him to assist in shaping responsive strategies to force driving change in business and culture today. In his current role, Markku heads up Chandos’ innovation initiatives. He served as president of the Integrated Project Delivery Alliance (www.ipda.ca) in Canada which has published “IPD: An Action Guide for Leaders,” several influential IPD research studies and provides IPD training for industry. Markku also held positions at the American Institute of Architects, where he was a joint content editor in the development of the AIA’s “Integrated Project Delivery: A Guide”.