What is Integrated Project Delivery?

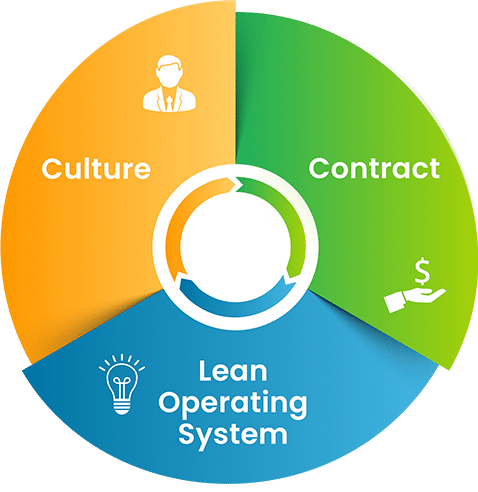

Integrated Project Delivery (IPD) – an approach that integrates people, systems, business structures and practices into a process that collaboratively harnesses the talents and insights of all participants to optimize project results, increase value to the owner, reduce waste, and maximize efficiency through all phases of design, fabrication, and construction. (American Institute of Architects)

Key Components:

- Multi Party Contract -

- At least the Owner, Primary Designer and Primary Builder

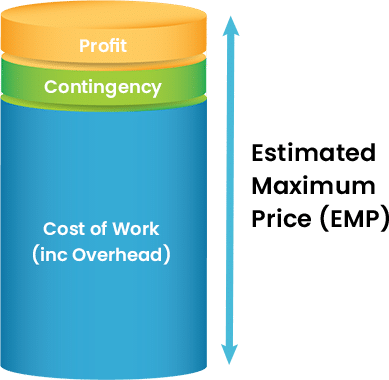

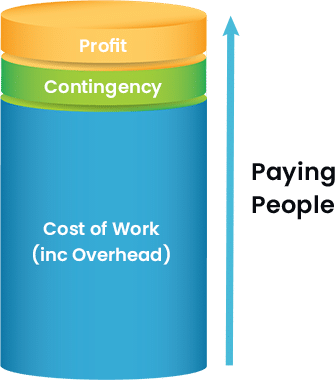

- Single Contract Amount Including Contingency

- Profit at Risk for Partners to the Agreement

- Guaranteed Costs for Partners Based on Audits

- Shared Savings if Project Delivered Under Budget

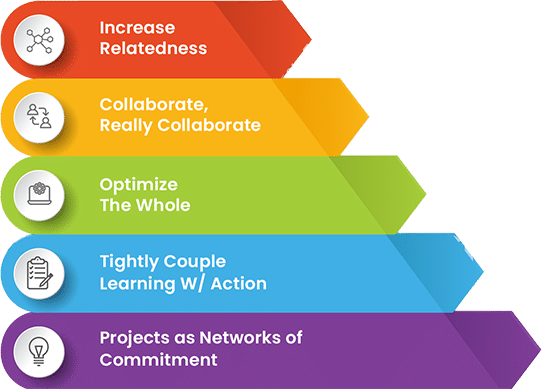

- Implementation of Lean Concepts, Practices and Tools

- Intentional Creation of a Collaborative Culture

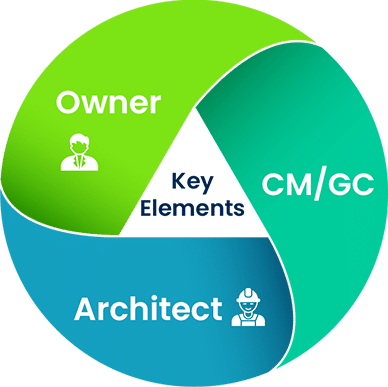

Key Elements of Integrated Project Delivery Contracts

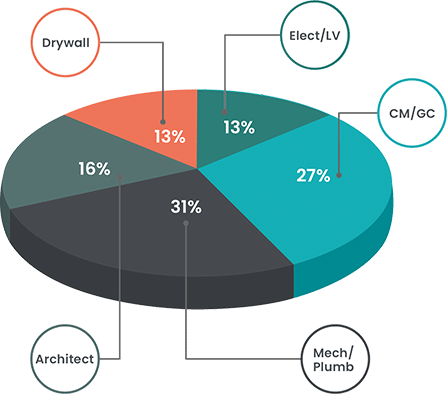

IPD Contracts consist of at least three parties:

- Owner

- Lead Designer / Architect

- Lead Builder / General Contractor

They may also consist of more parties in a Poly Party agreement. Example of other parties:

- Structural Engineer

- Mechanical Engineer

- Electrical Engineer

- Mechanical Contractor

- Electrical Contractor

- Concrete Contractor

Design and Construction included in a single contract.

- Primary Designer

- Design Sub Consultants

- Primary Contractor

- Trade Partners

- Primary Designer

- Design Sub Consultants

- Primary Contractor

- Trade Partners

These costs are typically audited to separate out direct labor burden, indirect labor burden, home office overhead and profit.

Guaranteed Costs for Primary Partners with 100% of Profit At-Risk

- Profit of Each Party is Put in a Pool

- Collective Profit is Often Called a Risk Pool

- Each Company Contributes their Profit

- Each Company has a Proportionate Share of the Pool

- When Costs Exceed Budget, the Pool gets Smaller

- When Costs are Under Budget, the Pool gets Larger

- When Costs are Under Budget, the Pool gets Larger

- The Total Cost Matters, Not Individual Performance

- One Company may be Under Budget and Lose Profit if the Whole Project is Over Budget

- One Company may be Over Budget and get a Bonus if the Whole Project is Under Budget.

Costs for Partners are Paid Each Month Based on Actual Costs

- Labor is Billed Based on Time Cards

- Labor is Paid Based on Audited Rates

- Material is Paid Based on Actual Invoices

- Overhead for Designers is Included in Rates

- Overhead for Construction is Applied on Direct Costs

- Overhead is Capped Based on the Original Contract Value for Each Party

- Lump Sum Subcontracts are Paid on a Percent Complete Basis

- Profit is Withheld on Each Invoice for Partners

- Profit May be Released at Milestones if Financial Perfomance is Projecting Under Budget

- Team Report their Cost to Complete Projections to All Team Members on a Monthly Basis

Pros and Cons of Integrated Project Delivery

Pros

Why is IPD a Model for Consideration?

- Financial alignment of design and construction.

- Financial performance based on overall project outcome not individual firm performance.

- Profit is at risk if project goals are not met around schedule and budget.

- Team has "skin in the game" for activities during preconstruction.

- Traditional silos removed to allow collaboration.

- Complex projects can be collaboratively developed in new ways.

Cons

What are some of the Challenges with IPD?

- Upfront investment required early in the project (cashflow cannot be delayed).

- There is a diminishing return on preconstruction spend if design/permits take longer than planned.

- Without adequate time and complexity on a project, it may not be possible to find savings to cover the upfront investment.

- Owner's does not have a firm fixed cap on cost at the start of the project (it is debatable whether they ever really do in any delivery model).

Testimonials

Renee Cheng, Professor and Head of the School of Architecture at the University of Minnesota, reports out on Myths of Lean and Integrated Project Delivery after a study of 10 IPD Projects.

This study confirmed the following concepts!

- Choosing the right people is more important than the delivery method and behavior can be driven (partially) with a contract.

- Lean tools are flexible and IPD contracts are NOT too complicated.

- New teams to Lean and Integrated Project Delivery can be successful. Lean and Integrated Project Delivery work on more projects than just Large, Complex Healthcare ones.

- Owners can, and do, get best value while the team earns a profit plus additional incentive. These are not mutually exclusive.

- IPD and IPD-lite are NOT the same: financial incentives and release of liability really do drive better results.

James Pease, a Health Care Owner's Representative, reports out on the experiences with a commitment to delivering large capital projects with Lean and Integrated Project Delivery.

Key Highlights!

- Improvement in projects leads to better patient care.

- IPD produces greater schedule and budget reliability.

- Design and Construction teams make more profit with less risk.

- Improved reliability leads to improved trust within the Owner Organization between executives and project leaders.

- Lean tools lead to success in a collaborative environment.

IPD Resources Available on Amazon

Integrated Project Delivery - An Action Guide for Leaders

An easy to use handbook for implementation

- Is IPD right for you and your project?

- Path to Contract - Establishing Common Purpose

- Owner Alignment

- Team Selection

- Contract Workshop

- From Beginning to End - Ongoing Considerations

- Team Management

- Financial Organization

- Lean Thinking

- Early Work - Processes and Tools

- Later Work - Maintaining Momentum

- What Goes Wrong and What We Can Do About it.

Integrating Project Delivery

A College Level Course on Integrated Project Delivery

- Upfront investment required early in the project (cashflow cannot be delayed).

- There is a diminishing return on preconstruction spend if design/permits take longer than planned.

- Without adequate time and complexity on a project, it may not be possible to find savings to cover the upfront investment.

- Owner's does not have a firm fixed cap on cost at the start of the project (it is debatable whether they ever really do in any delivery model).