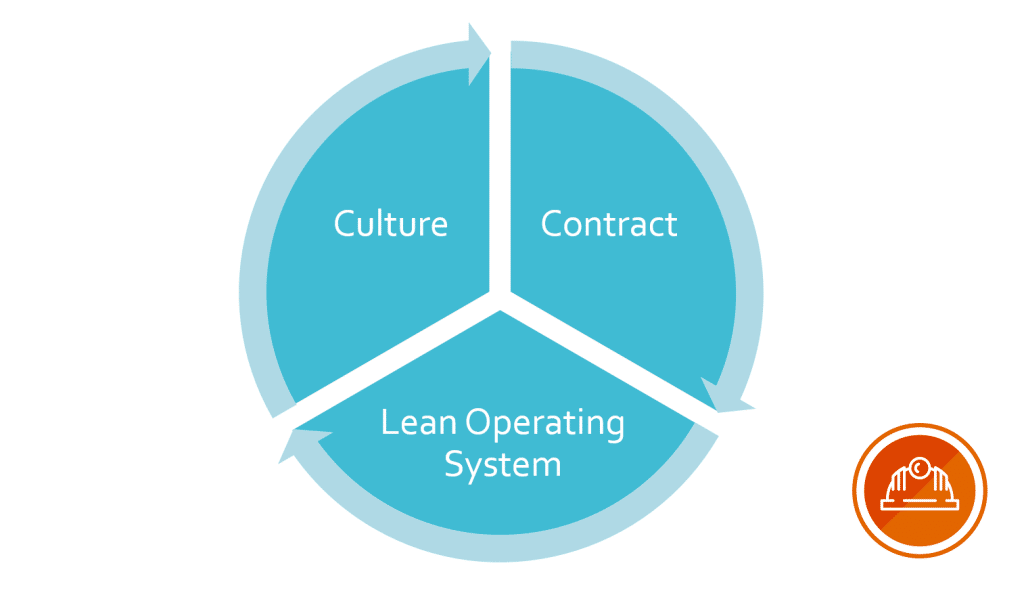

How I Implemented the First IPD Project in Norway

A few years ago, the University of Berkeley invited me to give a presentation to a group from Norway that was interested in learning more about IPD. I was one of several presenters and will never forget what one of the Norwegian visitors said to me after my presentation. He […]

How I Implemented the First IPD Project in Norway READ MORE