In the Lean Integrated Project Delivery (IPD) Community, we have all heard of Plan-Do-Check-Act. We understand that it is the cycle to create continuous improvement, one of the foundational pillars of Lean and IPD. Yet why is it so difficult to implement improvement? We often neglect to implement the “Act” portion of PDCA.

In this article, co-authored by Daniel Drouin, we suggest opportunities to shift our mindset to allow continuous improvement from Lessons Learned on IPD projects.

How many times do we find ourselves running into a problem that has happened to us or near us in the past?

The world of design and construction is chock-full of challenges and opportunities to get better. Most people don’t like when a problem arises and think: “Geez, this always happens!” It can be frustrating and zaps morale.

Yet for some reason, we often find ourselves missing the opportunity part of the equation and keep running into the same problems over and over again. We hold Plus/Deltas at the end of a meeting, only to have the same Delta four weeks in a row. Maybe we figure out how to put an end to a certain problem on one project. But then, it pops up again in a new environment down the road.

A few years ago in a week-long problem-solving class for ten participants, all from the same company, something interesting came to light. On day three, the participants were to bring a real problem to class so that we could use it to do a root cause analysis of the problem. The first participant began to explain his problem to the group. He thought it was a fairly unique problem, as he had been in the industry for over a decade and had never heard anything about it before. Imagine his surprise when two of the other participants excitedly shared that they had the same problem in the past. Three people in the same company, based out of the same office, had all experienced this same very challenging problem. And each of them thought it was unique to them.

Implementing the improvements adds value to the process

Many organizations have very robust processes for capturing Lessons Learned from projects, however, too often they get filed away and forgotten until we see issues repeat themselves again. Managers facilitate conversations and then document Lessons Learned without actually implementing the improvements. At times, people don’t even bother looking at them once they are done with the project, however, they still persuade people to collect them. Often it feels that collecting the Lessons Learned means that the project is over. Taking the time to capture Lessons Learned is a mere fraction of the value that comes from the process. Implementing the improvements is where the real value comes from. Let's stop wasting this valuable knowledge and start using it to our advantage.

Some project teams take the time to recognize those Lessons Learned as they are being learned (often called Retrospectives). This allows them to put preventative measures in place while they are still on the project as well as pass those lessons to other teams in a more timely fashion. Those teams perform at a much higher level because they continue to improve throughout and after their projects.

Lean equals respect for people and continuous improvement

The tools alone do not make us lean. It is the relentless pursuit of continuous improvement coupled with respect for people that makes us lean. Yet lean projects often repeat the same problems, which in itself is not lean.

Companies that truly practice continuous improvement will run into fewer repeat problems because they don’t just look to gather information and understand the cause of problems, but they truly embrace the learning and apply preventative measures to solve the problems. They focus on making today better than yesterday, and tomorrow better than today. Continuous improvement is at the forefront of what they do.

As construction teams consist of many members from different organizations, continuous improvement (or lack thereof) is further compounded. Not all of the team members share the same culture, interest, or tenacity when it comes to the continual application of learning, and it can be difficult to build this momentum if the team does not articulate and plan for the intention.

Opportunities to shift our mindset

There are many things that can prevent us from implementing improvements to avoid recurrence of the problems. Let's look at some of the common reasons why teams avoid improvement, along with why we propose they are simply myths, and how we can shift our mindset to see them as opportunities.

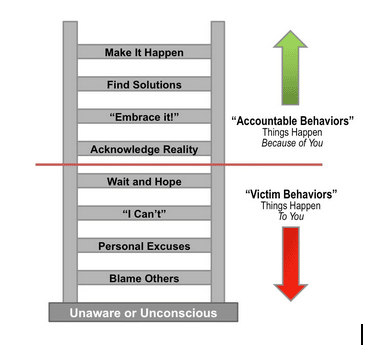

- Lack of psychological safety - Often people don’t feel they have the voice, the authority and/or the responsibility to implement process changes to improve. However, most of the time, all it takes is an intentional shift in how we think about the problem and solution. While psychological safety is a very real feeling, we sometimes allow it to become an excuse for inaction. Referring to the Accountability Ladder shown below, we simply want to shift from being a victim to being accountable, taking ownership of the situation and making things better.

Image: Forbes

- Lack of time - The construction industry is a fast-paced world. We always seem to be moving with a high sense of urgency. To stop, reflect, problem-solve, and implement solutions feels too time-consuming to do it well. What we neglect to recognize when we do a quick fix on a problem is that, if we don’t take the time to prevent it from recurring, it will appear again and again, taking far more time than it would if we just put our learning into action from the start.

- It is too expensive - Sometimes there is a financial cost to implementing an improvement. We often allow the view of this initial outlay of dollars to keep us doing what we have been doing in the past. Instead, if we take time to quantify the costs (including soft costs) of what the improvement will be saving multiple times in the future, it will often save more than we spend to fix it.

- Ownership - The mentality “It’s not my job, someone else should do that” might be useful in the moment, but when we run into that same problem again and again, it doesn’t do us any favors. Instead, revisit the accountability ladder.

- It’s hard to get every improvement - Yes, it is challenging to improve every time. It takes discipline, time, and energy to work on preventing the recurrence of problems. We don’t suggest that you try to tackle them all at once. Prioritize them by thinking about the most impactful, the most urgent, and those that are likely to recur soon. Then look for a second. Tackle them one at a time, allowing your team to build momentum around solving problems. As you recognize the time savings, you can use that time to solve more problems.

- The project is over. We’re missing half of the team and we just don’t care anymore - Rather than allowing our teams to fall into this trap, we can focus on having ongoing Lessons Learned (or Retrospectives) throughout the project. Some teams set these up on a regular cadence, some teams hold them at the end of milestones, and other teams hold them when they experience a specific breakdown. There are many opportunities to hold Retrospectives and still have time to implement the improvements before the end of the project.

How can we benefit from the A in PDCA?

What are the real benefits of Plus/Deltas, Retrospectives and Lessons Learned? By using the actions that come out of these processes, you can continuously improve processes, people, products, and projects. The captured information feeds into processes and best practices. It can increase effectiveness, efficiency, and rapidly impact project outcomes. Learning from our own mistakes is the fastest way to learn. Another benefit is that we now have the ability to repeat successes and avoid repeating failures. Following through with these results generates new knowledge that the team can share to promote organizational culture growth.

During this phase of the process, analyze and organize the Lessons Learned to determine how to apply them. Make sure that you’ve gotten to the root cause of the problem (or the success) and you have actionable ways to implement the improvements. Then decide whom to train on the new improvements and what project management processes to update. Create an action plan outlining the necessary steps, responsible parties/departments, resources, and a timeline.

There are many parties beyond our project team with whom you can share Lessons Learned . Think of other project teams, other organizational departments, and even our industry as a whole. Simple ways to share them are:

- Lunch and learns

- A quick virtual coffee with peers and colleagues

- A daily huddle.

Get into the habit of sharing what you have learned and not just storing the information. Create easy-to-access folders in a shared drive (i.e. Google Drive or Sharepoint), making them available to the project team as well as other stakeholders and teams in the organization.

Some best practices to implement Lessons Learned are:

- All stakeholder involvement

- Document both good and bad

- Start with: What did we do?

- What went well?

- What could have gone better?

- What do we want to stop doing?

- What do we want to start doing?

- What do we want to keep doing?

- Make the learnings visible and accessible

- Review learnings throughout the project

- Incorporate a regular cadence of Retrospectives (at the end of milestones, biweekly, or some other cadence that works for your team)

- Share

- Reuse and encourage feedback (post-project)

A new way to think about work

Taking the time to identify and implement improvements makes work in the future better. We can avoid repeating the same problems and spend our time and energy on new work and solving new challenges. While we’ve been discussing this in the context of a lean IPD project, there is no reason you can’t apply some of the same concepts to other project delivery models or even to our daily work within an organization.

Like so many things, implementing the A in PDCA with Lessons Learned and Retrospectives is not complicated nor complex. It only takes a shift in how we think about our work. The goal is to deliver value to our customers (internal or external). Think about how you can take advantage of the opportunity to improve your work and eliminate waste while you are doing your work. As a result, you will deliver better value to your customers.

Feature image: Tim Mossholder via Unsplash

More from these authors

Lean Transformation: Are You Talking Apples or Oranges?

Lean Transformation: Is Your Leadership Team All In?

5 Tips to be Successful in an IPD RFP

Related articles

Overcoming Resistance to Change

A3 Thinking for Powerful PDCA to Improve Lean Project Delivery