Since the popularization of quality circles in the 1960s, companies around the globe continue engaging front line employees to improve their work using variations of PDCA, a scientific method for problem-solving using four steps:

- Plan a change or test aimed at improvement.

- Do carry out the experiment.

- Check (study) the results.

- Act (adjust) to adopt the change, abandon it, or repeat the cycle.

Lean design and construction practitioners use PDCA and A3 Thinking to enter continuous improvement cycles and impact operational performance to improve project delivery.

What is the A3 problem-solving method?

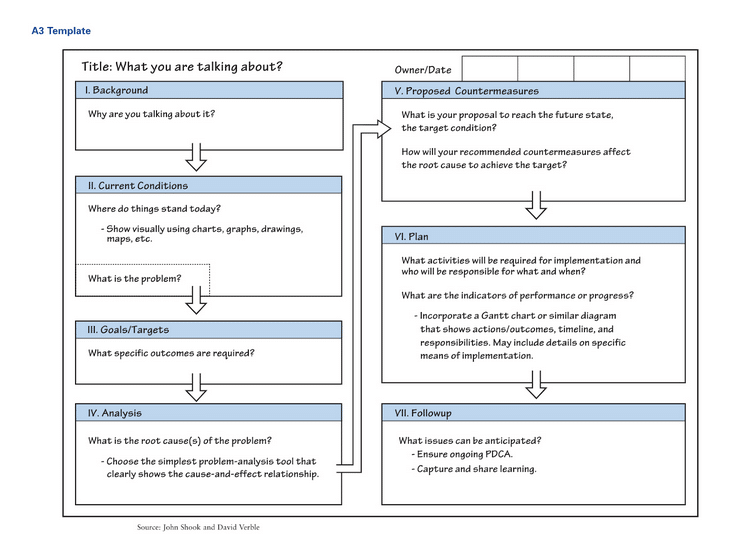

The Lean Construction Institute Online Glossary describes A3 as:

A one-page report prepared on a single 11 x 17 sheet of paper that adheres to the discipline of PDCA thinking as applied to collaborative problem solving, strategy development or reporting. The A3 includes the background, problem statement, analysis, proposed actions, and the expected results.

I recommend reading Managing to Learn: Using the A3 management process by John Shook. The following A3 template from the author is available as a free resource on the LEI website. And you don’t have to use every section in your A3, the template is a framework to help organize your PDCA approach. The format is far less important than the process and thinking behind it.

Visualize your project, take aligned action, and improve the outcome

Design and construction teams are using A3s to problem solve every day. Their single 11 x 17-inch sheet is typically organized into several sections to allow the problem solver (author) to fully grasp the issue, include relevant business background information, explore the current situation, and set goals. With other sections including root-cause analysis, countermeasures, and an action plan, the author has a unified place that helps to visualize the whole process, gain alignment with others, and sustain improvement.

Teams in design and construction are using A3s for the following processes:

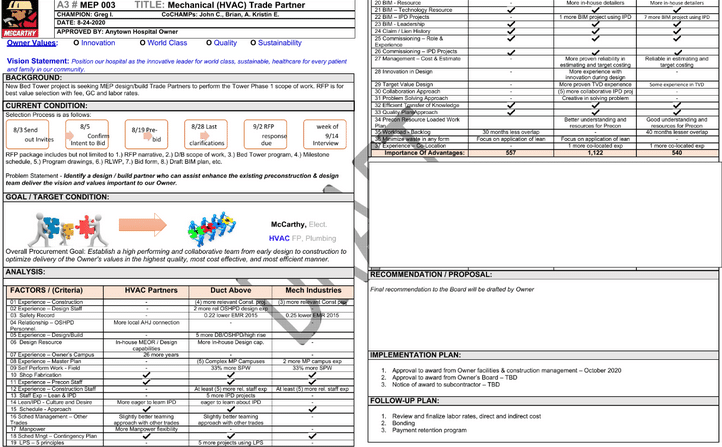

- Request for proposal (RFP) responses

- Request for qualification (RFQ) response

- Set-based design alternative evaluations

- Value engineering

- Choosing by Advantages for sound decision-making

- First-run Studies for work sequencing

- Process mapping and future state improvements, also for value stream mapping

- Analyzing Last Planner System variance

- Improving site logistics and flow

- Business strategy planning and execution

- Company-wide initiative planning and execution

- New job role creation

- Succession planning

- Training (new and improvement of existing)

- Personal and professional development

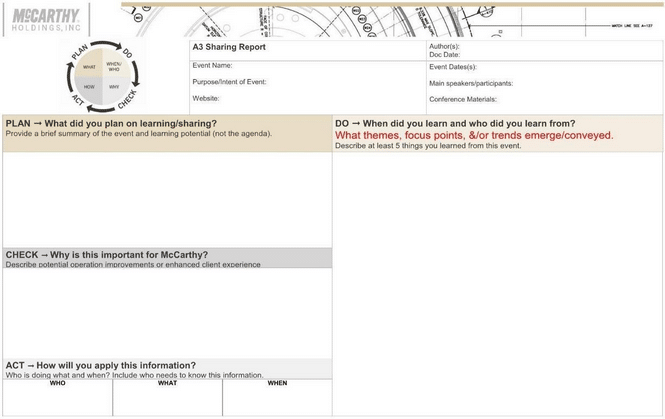

- Sharing conference learnings with peers

- Improving Lean adoption

How to use A3 planning

Ready to start using A3s?

Answer these questions from John Shook to help guide you:

- What is the problem or issue you are trying to solve?

- Who owns the problem?

- What are the root causes of the problem?

- What are some possible countermeasures?

- How will you decide which countermeasures to propose?

- How will you get agreement from everyone concerned?

- What is your implementation plan - who, what, when, where, how?

- How will you know if your countermeasures work?

- What follow up issues can you anticipate? What problems may occur during implementation?

- How will you capture and share the learning?

The secret of using paper and pencil

Studies found that handwriting increases neural activity, sharpens our brain, helps us learn, and unleashes creativity.

So it comes to no surprise that experts in A3 recommend starting with the humble pencil on a piece of paper. See the first example below by Eric Ethington, a decades long A3 user and coach, using a file folder and pencil.

My A3 skills were dramatically improved after attending a joint Lean Construction Institute and Lean Enterprise Institute (LEI) A3 workshop led by Eric. I learned how to coach and guide others to dive below surface level problem-solving and do deeper analysis to expose and eliminate underlying root causes while allowing the A3 author to keep responsibility while learning.

The following design and construction A3 examples all started with a piece of paper before they were built with word processing and PDF software.

Best practices and what to avoid

As the national Director of Lean Construction for McCarthy, I have worked with projects teams and individuals engaged in PDCA using the A3 problem-solving approach across the United States since 2016. That includes working with other Lean leaders who volunteer with the Lean Construction Institute’s Congress Planning Teams since 2017. I have been involved in A3s that have helped improve multimillion-dollar projects and multibillion-dollar enterprises.

Here are some Do's and Don'ts based on my A3 experiences.

| Do | Don’t |

|

|

Further reading

Managing to Learn, Shook, J., Cambridge, MA: Lean Enterprise Institute, 2008.

Three Ways Handwriting with a Pen Positively Affects your Brain

More from this author

International Lean speaker, a serial intrapreneur, Felipe Engineer-Manriquez is a committed Lean practitioner with two decades of construction industry experience. He is an active contributing member of the Lean Construction Institute and an approved instructor/facilitator. Engineer-Manriquez was honored with the Lean Construction Institute (US) Chairman’s Award during the 21st Annual LCI Congress (Oct. 14-18, 2019) in Fort Worth, Texas, for contributions to the Institute and the design and construction industry as a whole.

Felipe works with executive leadership and guides senior leaders for strategic planning and improving work processes. He works directly with regional VPs of operations to ensure safety, quality, production, and net margin enhancement. He mentors designers/engineers, and project teams across the nation. He has more than 20 years of experience in construction and more than ten years of experience in business strategy implementation. Felipe has a Bachelor of Science in Electrical Engineering, an MBA, and holds active leadership roles in the Lean Enterprise Institute, Construction Industry Institute, and other business organizations.

He is a Jeff Sutherland Certified ScrumMaster® with years of weekly sprints moved to Done and user of Scrum to lead thousands of fellow construction professionals via guided interactive learning. Felipe also currently serves as the chair of the Construction Industry Institute Collaborative Scheduling Research Team (18-362).