When HGA agreed to join McGough Construction on their first contractual IPD project, I jumped feet first into a trial-by-fire arrangement. Our project – McGough’s own new corporate headquarters in Roseville, MN – was a unique one, since McGough served a dual role as both Owner and Contractor. As trusted partners with a long history of working together, our collaboration proved an ideal testing ground to try innovative approaches to delivery, risk management, and cost savings to promote our shared commitment to design quality, craftsmanship, and regional pride.

I admit that one concern I had about the IPD process was that the focus on cost-effective solutions would overpower decisions that led to design excellence. Luckily, as a client, McGough valued our design input and we worked together to focus our work on design elements that reflected McGough’s brand, while together seeking opportunities for functional value.

We were joined by other leading Twin Cities building professionals, including Schadegg Mechanical, Gephart Electric, and Twin City Glass, to finalize our first poly-party contract. As IPD novices, we brought on an attorney to help finalize the contract and an IPD “coach” to assist with the process, both in design and construction.

While most IPD projects generally are large-scale buildings such as hospitals, this smaller commercial project, at 55,000 square feet in a converted trucking terminal, tested the agility and flexibility among our team members, while we all balanced time between this and other client obligations. Our success was driven by a shared vision of team collaboration, architectural craftsmanship, and cost savings.

How we converted a trucking terminal into a modern workspace

It didn’t hurt that the design problem McGough gave us was a fun one: how to convert a former trucking terminal into a light-filled, modern workspace? The terminal’s 25,000 square-foot bow-truss area was structurally reinforced and walnut-blasted, restoring the wooden roof structure to its original splendor. Within this area—the heart of the headquarters—we arranged flexible workstations, huddle areas, phone rooms, break areas, and glass-walled conference rooms, all daylit from new windows that replaced the former overhead doors and a new skylight down the center of the warehouse.

To accommodate the program, we needed space beyond the original terminal, so we demolished the non-descript existing east and west wings and added a two-story addition and entry. This addition presented opportunities to showcase McGough’s legacy of concrete and masonry craftsmanship. The iconic Saint John’s Abbey Church in Collegeville, MN – McGough’s first major project in the early 1960s – served as inspiration.

One focal element of the design – a new grand stair that connected our front entry with the office spaces in the addition above – became an opportunity to showcase the best of McGough’s concrete craftsmanship. The IPD process allowed us to partner with McGough’s concrete specialists early in the design process. We worked together to innovate on the detailing and shaping of the stair to design something that wasn’t only cost-effective and efficient to build but also beautiful in its result.

The addition’s exterior walls feature hand-laid brick, displaying the craftsmanship of McGough’s own masonry team. Once again, we worked throughout the design process with McGough’s masonry team to explore multiple brick types and detailing options before finalizing our design direction. Involving our experts from Twin City Glass allowed us to consider multiple ways of achieving our deep window recesses with framed openings, before settling on a custom metal solution that also proved cost-effective.

Before & After

All photo credits incl. feature image: 2020 @Corey Gaffer, courtesy of HGA

Trust and respect foster team collaboration

One key to our success – having never worked in this way before – was that many of us had previously established relationships and familiarity and respect for each other’s work. To start, we formed a 6-person project management team (PMT), with a key leader from each firm in the IPD contract, to streamline consensus throughout the 19-month schedule that included nine months of design and 10 months of construction. As members of the PMT, we worked to establish a culture of open communication and dialogue throughout the project, which was only possible due to mutual trust and respect. Having continuity of personnel on our PMT meant that we were all in it from start to finish, and we learned to recognize each other’s strengths and weaknesses. The relationships we formed early in the project saw us through the sometimes-heated debates around cost pressures and design decisions. I was proud to be part of a team where my voice as an architect was always heard and respected by my counterparts in construction.

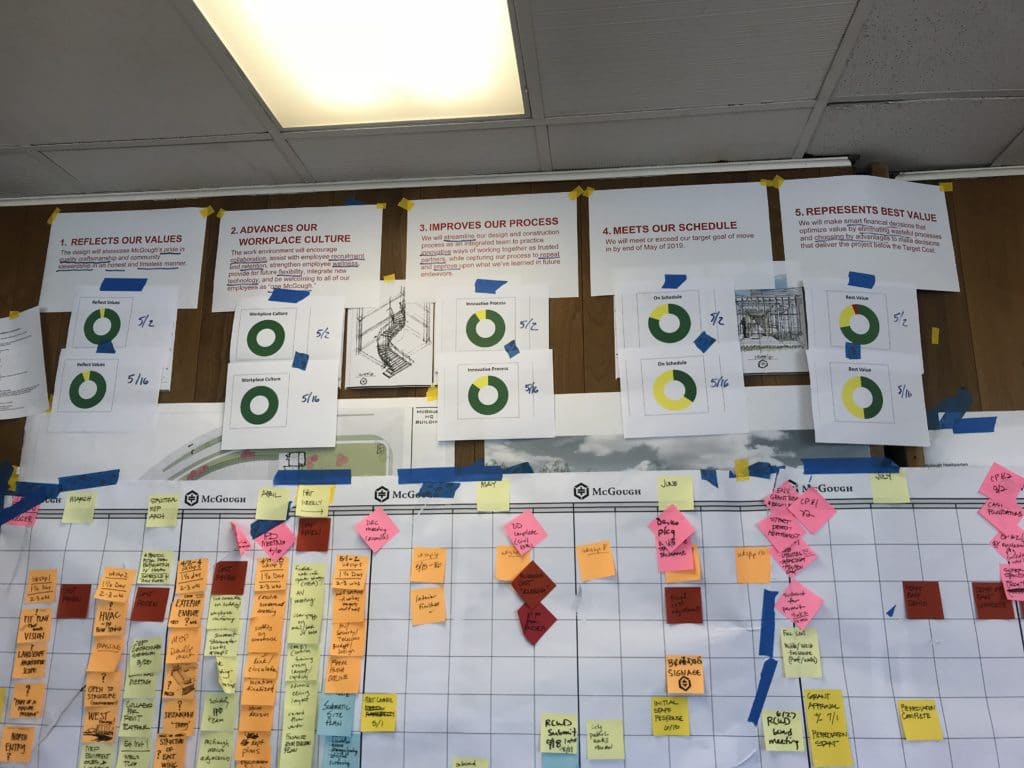

Our focus on collaboration also extended to our full project team. Beginning in schematic design and continuing through construction documents, all stakeholders gathered in the Big Room for bi-weekly day-long workshops to define and document project goals. Having a dedicated space to leave progress drawings pinned to the wall and reference previous work allowed us to make quick progress from week to week. Each workshop was structured as a charrette, in which the design evolved from early massing and site planning to space planning, materials selection, and construction details. At the end of each workshop, we completed a Conditions of Satisfaction form documenting how well the team achieved our goals. Potential concerns were vetted by the entire team and action items assigned and documented on the Constraint Log, resulting in proactive problem-solving.

We kept this pace of meeting through construction, starting in February 2019 until completion 10 months later. Our project architect and structural engineer often worked out of the jobsite for a few days every week, allowing quick and easy access to conversations and problem solving when needed. McGough’s accommodation of them on site also allowed them to multitask on other work if needed, making sure they spent efficient use of their time. Weekly coordination meetings followed the protocols we established in the Big Room during design, including documentation of our Conditions of Satisfaction and weekly maintenance of our Constraint Log.

Images: HGA

Results: Cost Savings & Shared Rewards

Understanding the impact of our design decisions on the cost of the project was a weekly focus, from early in design through construction completion. The IPD contract allowed all stakeholders to have access to this information in a fully transparent way. We kept the cost estimators on their toes by asking them to help us with mini-cost estimates throughout the process, in order to help select systems and integrated design solutions that were the most cost effective, prior to waiting for milestone cost estimates to be completed. As we transitioned from design to construction, we used visual data tracking to review overages and compare current trends to the Conditions of Satisfaction.

Early in the project, we divided the cost estimate into “Work Groups” and established a leader of each to help track the estimate and costs within their scope. These included Site, Structural, Exterior, Interior and MEP systems. Work Group leaders took on roles we may not have otherwise had. For example, during the design phase, we empowered the structural engineer to take ownership of the structural estimate, working with McGough’s estimators to understand the impact of the structural decisions. Our designers benefited from direct access to cost data to help select finishes and design details that balanced our aesthetic goals with our desire for best value.

The PMT challenged McGough to maintain these workgroups throughout the construction phase, which meant a tweak to their traditional accounting methods. The benefit was that we as a PMT could continue to review the progress of each workgroup throughout construction, understanding where we had overages and how we could adjust the project to maintain our overall budget. Our monthly PMT meetings also included review of scope changes and additional Owner requests, allowing all of us to have a much fuller understanding of how and where the money was being spent.

Our work paid off; the project was completed under budget and all of the signatories of the IPD agreement benefited from the shared rewards of the project.

Keys to success: transparency, open communication, and collaboration

While IPD usually represents a contract between design and construction partners who may never have worked together before, the IPD arrangement here worked because of the long-established trust between all participants focused on open communication. It was important to have adaptability, flexibility, and openness throughout the process and the willingness to adjust as we went along.

As the first IPD project completed for many of the partners, the McGough Headquarters was an opportunity for industry specialists to come together as trusted partners, experiment with a new project delivery type, and showcase McGough’s commitment to quality construction.

In Summary

Although I’m not sure when I’ll experience another IPD contract—and as the only woman involved in the six-member PMT meeting—the lessons I learned on this one still apply to my other projects moving forward. As an architect, I now have a deeper understanding and more empathy for the roles of the many other disciplines involved in construction, from the contractor, engineer, and subcontractors. This collaborative approach, where all building specialists are working together to achieve common goals despite differences in technique and expertise, is one that I hope to continue to foster and implement in all of my projects ahead.

Further reading

IFOA and the Advantages of Bringing People Together Faster

Rebecca Celis, AIA, LEED AP BD+C, is a Principal at HGA. Organized and enthusiastic, Rebecca thrives in interactive team environments and believes that integrated, sustainable design results from a combination of teamwork and clear communication. Specializing in education facilities for the arts, sciences, and other learning environments, she fully immerses herself in understanding the unique program and facility goals of her clients. Rebecca makes certain that her design teams integrate the multi-faceted and unique planning criteria of an institution’s spaces from early programming definition to discipline coordination in working drawings. Her ability to plan and integrate complex systems into highly-functional and effective spaces is reflected by the success of her projects. Recognized for her leadership and contributions to the design industry, Rebecca was awarded the AIA Minnesota Young Architects Award in 2015.