Have you ever been on a construction project where the owners, architects, engineers, and contractors have used their own tools, which lacked interoperability? Did you experience data loss because it had to be entered multiple times?

As Executive Director of the Construction Progress Coalition, a non-for-profit organization focused on the advancement of open standards adoption in construction, I am an evangelist for Common Data Exchange (CDX). CDX blends digital language translation with a Lean framework to document the optimal process for a given use case where data is exchanged between different project stakeholders using their technology platform of choice. Ultimately, the CDX framework exists to help project stakeholders define their data interoperability requirements and communicate them more effectively.

For example, when it comes to a change order, a Request for Information (RFI), or a submittal, everyone knows who's sending it, who's receiving it, what is the question, and what are the attachments. As more project management platforms move to the cloud, this enables API integration. But, those API capabilities also have data and process standards that need to be defined and communicated in a CDX playbook that memorializes those use case requirements. This combo of API capability and CDX documentation allows project teams to avoid duplicate data entry and, as a result, reduce soft waste.

And it should be no surprise that our industry has a lot of room for improvement in this area.

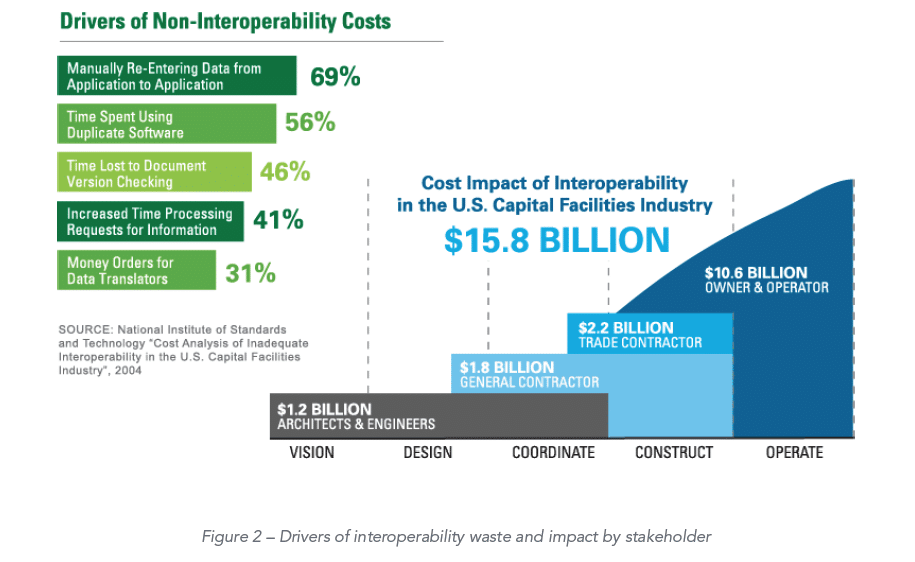

US construction industry produces more than $15.8 billion in soft waste every year

The National Institute of Standards and Technology found that “the US construction industry generates more than $15.8 billion every year in waste due to a lack of data interoperability between project stakeholders.” You can read more in our 2019 report Improving RFI Efficiency & Insights through a Common Data Exchange for ELECTRI International.

Illustration: ELECTRI International: Improving RFI Efficiency & Insights Through a Common Data Exchange

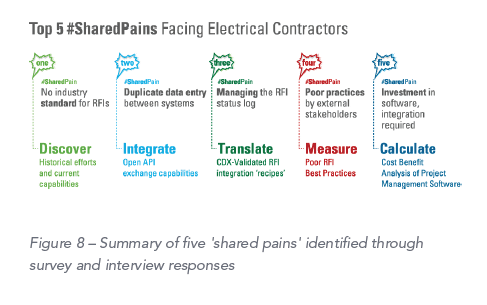

Duplicate data entry was named as one of the top five shared pains faced by electrical contractors and their external project delivery stakeholders. The five pains are:

- Industry standardization

- Duplicate data entry

- Status log management

- External stakeholders

- Technology ROI

Illustration: ELECTRI International: Improving RFI Efficiency & Insights Through a Common Data Exchange

As the root causes of this waste, we identified “manual data entry from application to application” and “processing of requests of information”. Which means that project data interoperability (or lack thereof) is a major contributor to the overall waste generated on a project.

Construction technology still heavily fragmented

According to McKinsey, “construction is one of the least digitized industries, just ahead of agriculture and hunting.”

Ten years ago, the construction industry started embracing digital solutions, which initially addressed basic needs, such as digitizing paper-based information or improving design capabilities. Later on, suites of integrated solutions appeared. Despite many efforts, our industry is still figuring out where we’re at with digital transformation.

“Construction technology is still a heavily fragmented, point-solutions-driven market with ample opportunity for integration plays that create either new platforms or attractive component acquisition targets for growing incumbent platforms. This fragmentation is more evident when analyzing construction tech offerings across the project life cycle.” (McKinsey, August 2020)

Changes in process and mindset are required

Teams who embrace interoperability between structured Project Management solutions, can harness their data much better. However, what we found is that concerns about data sharing and security can arise. This is especially true on traditional hard bid contracts. Our research also showed that beyond the technical requirements, teams need to make fundamental changes in process and mindset to overcome the hurdles to digital transformation.

The central question is how do we communicate the requirements of technology in a way that is lean and very tactile at the same time, similar to the magnets on a whiteboard.

Or, in other words, how do we change habits and measure progress?

The use of a Key Performance Indicator (KPI) dashboard is a great start. Dashboards can help analyze Request for Information data and generate valuable insights. However, dashboard analytics across the organization cannot happen until we fully embrace digitalization. To eliminate duplicate data entry, all project stakeholders must have clear rules of engagement for documentation, management, and transfer of RFI data.

Which leads us to the next challenge:

Project Data Interoperability and the difference between digitization and digitalization.

Digitization is the process of translating data from analog, “human-readable”, information into a “machine-readable” digital format. This allows us to track and search RFI, but it does not solve the problem of double entry. In fact, it often compounds the problem into triplicate or quadruplicate entries.

Digitalization, on the other hand, is the transformation of process and product to align with those new digital requirements.

Remember how Uber disrupted transport services by leveraging new technology for an existing service to make the traditional process of hailing a cab more convenient and valuable?

Digitalization is the tipping point where multiple pieces of technology collide to create a new value that disrupts an existing industry.

Market swamped with ConTech solutions

Since the iPad’s 2010 release, the construction jobsite has never been the same. Project Managers and field supervisors are bombarded with hundreds of new technology solutions, each aimed at improving quality, efficiency, and data transparency. However, none has become the “silver bullet” between the needs of the field staff, office staff, and external project stakeholders.

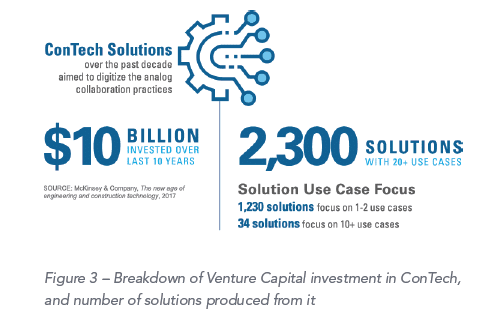

Over the past decade, more than $10 billion in venture capital investment has gone into construction technology (ConTech), producing more than 2,300 solutions aimed at digitizing the analog practices that remain status quo on the majority of US construction projects.

Illustration: ELECTRI International: Improving RFI Efficiency & Insights Through a Common Data Exchange

People, Process, Technology

When addressing the compounding challenges between integrating standards and motivating adoption, the answer cannot lie simply with technology. The “full-stack” solution to construction’s productivity challenge lies at the intersection of technical capability, marketplace viability, and the individual incentive to adopt.

Which means we have to start with the people on the project, their daily habits, and willingness (or resistance) to change.

Common Data Exchange (CDX)

What we found in our survey is that, ultimately, two factors motivate electrical contractors to adopt Open API integration of RFI data. The first is the digitization of the RFI for risk management and historical analytics. The second is the digitalization of RFI workflows to eliminate duplicate data entry between external PM platforms.

The Common Data Exchange (CDX) framework addresses these compounding factors by helping project stakeholders to collectively authorize the level of data transparency and exchange workflows. CDX defines the project-level protocols and data field requirements that unlock the full potential of API integrations.

In summary

According to McKinsey, “the construction technology industry is still filled with players offering point solutions or limited suites.” However, there are trends towards a combination of multiple platforms that will coexist in the industry. The pandemic has forced many organizations to adopt digital transformation to stay in business and support the safety of their employees.

I believe that CDX exists to help the designers, builders, inspectors, and operators of our built environment share valuable information without wasting valuable effort doing so. The CDX Paybook is designed to help project teams structure the data within our project management solutions, our collaboration tools, and BIM. At the end of the day it comes down to collaboration, data, and alignment of how we want to communicate between the stakeholders of a construction project.

Stay tuned for my next article about the CDX Playbook or the future of RFI integration.

Download the survey

ELECTRI International: Improving RFI Efficiency & Insights Through a Common Data Exchange

More from this author

Do You Trust Your Lean Team Members?

How You Can Drive Construction Innovation Throughout Your Organization

Feature image: umberto via Unsplash

Nathan Wood, Founder and Chief Enabling Officer of SpectrumAEC, is an innovation thought leader across the Architecture, Engineering, and Construction (AEC) industry. Nathan’s experience with Virtual Design and Construction (VDC), Lean process improvement, and Integrated Project Delivery (IPD) has led him to realize how proven technology solutions can too often result in adoption failure and lost ROI. Nathan blends Emotional Intelligence (EQ) with Design Thinking strategy to help teams overcome adoption barriers through collaborative debate and mutual respect for different perspectives.

Outside of SpectrumAEC, Nathan continues to support industry progress through speaking engagements, industry research publications, and as President of the Construction Progress Coalition.