Complex capital projects across all industries, from health care, oil, gas, mining, manufacturing and power generation all have at least one thing in common. According to research performed by the Construction Industry Institute, they have a high probability of finishing late and over budget. It seems that the larger and more complex the project, the more likely it is to be significantly over budget.

There are many reasons why complex capital projects fail, as defined by finishing late, over budget, and or with significantly scope reduction. The delivery model and extent of early owner involvement are two common factors. Due to procurement laws, tradition, and a lack of knowledge, many projects are still awarded on a Design-Bid-Build (DBB) model where the actual builders of the project are involved very late in the design process.

Even with Construction Management at Risk (CM at Risk) or Engineer-Procure-Construct (EPC), the actual builders are involved late in the design process. The typical structure of contracts and risk transfer keep true feedback from being incorporated into the design in a way that makes the entire project better. There are many, many examples of large projects starting with the best of intentions, only to finish wildly late and significantly over budget with major reductions to scope.

After personally trying Design-Bid-Build and CM at Risk on many health care projects, I experienced many of the same outcomes – late and over-budget projects despite my best attempts and those of qualified, well-meaning team members to do the same. If we were all coming in with the right idea, why did we keep failing?

I spent the last 10 years working almost entirely on Lean Integrated Project Delivery (Lean IPD) as a means to deliver over $650M worth of health care projects in Northern California. Those projects finished with 90% of them completing on schedule and all but one completing under their original board funding amount. Why is it that by changing the delivery method – including implementing new technologies like Fieldwire – for a project, we can significantly improve the odds of completing on time and on budget?

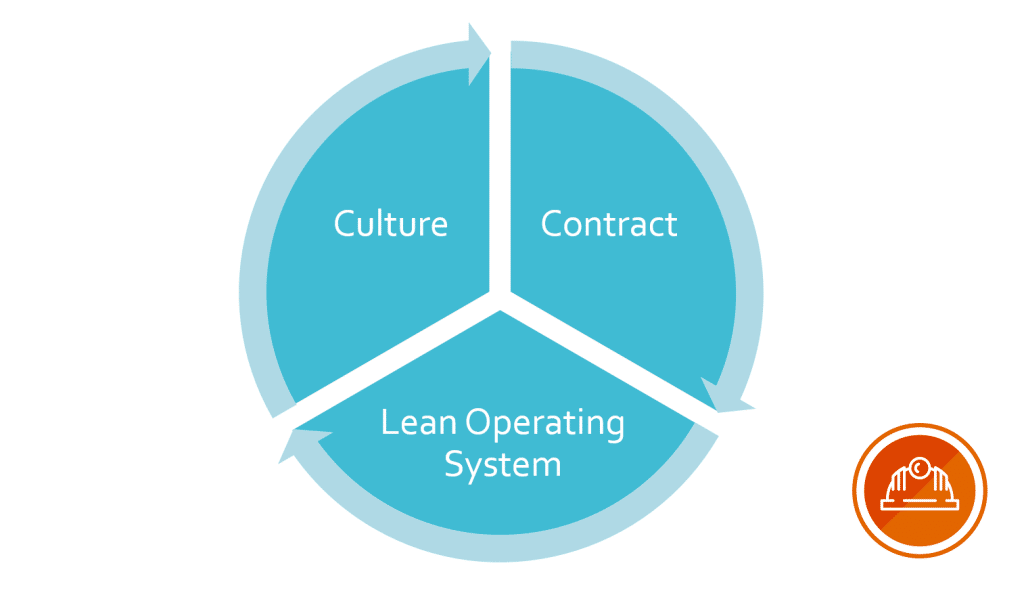

In distilling down the components of Lean IPD, I believe the most important components are:

- A collaborative validation process

- An aligned contract structure

- Target Value Design (TVD)

- The use of Last Planner® System (LPS)

- Intentional implementation of available technology

Many owners or project sponsors work on the business case for a project in a vacuum, isolated from knowledge of design and construction professionals. Once a business plan starts to come together, it drives a budget that makes the project feasible.

The owner then hires a design team to put together a set of design documents. Whether in CM at Risk or Design-Bid-Build, the amount of influence that the build team has early in the design is usually minimal. The owner contracts for the builder separately from the design team and sets up different incentives from those of the design team. The owner doesn’t usually drive processes and collaboration into the project and the contract structures force entities to protect their bottom line in a way that quickly can become adversarial.

In Lean IPD, the process follows the same timeline, yet at the same time the components look very different. They are:

Validation. As the owner starts to develop their business plan, they will engage a design and construction team. The team will come onto the project to help the owner build a business case that is supported by a design and budget that is achievable. Once the entire team agrees that the owner’s business need can be met within a realistic schedule and budget, the team documents the components of the project in a Validation Study (or similar). The owner uses this document as the basis for their complete funding request.

Contracting. Once the Validation process is complete and approved, the owner contracts for design and construction of the project through a single contract for design and construction. This contract may have only the primary designer and builder sign the contract or it can have many parties as primary signatories. The contract value includes a contingency for the team, audited costs are guaranteed and there is a shared savings plan. In exchange, the team agrees to put 100% of their profit at risk if the project exceeds the contingency amount. Errors and omissions are not changes (increases) to the contract amount in this type of agreement although everyone is paid their costs to complete the work.

Target Value Design (TVD). Instead of estimating the project at predetermined design milestones, the project team is continually tracking the cost of the project with a concept of TVD. In TVD, the team designs to the cost from the validation effort instead of estimating the cost of the design. With a continual focus on cost throughout the design phase, the team is encouraged not to draw anything until they have first confirmed that it is included in the budget instead of drawing something and then estimating how much it will cost.

Last Planner® System (LPS). Developed by the founders of the Lean Construction Institute, LPS is a holistic approach to project planning with five parts: milestone planning, pull planning, look ahead planning, weekly work planning and learning. While traditional construction schedules are often too detailed and burdensome to maintain, LPS consists of planning the work with the right people, at the right time, and at the right level of details. Teams focus on improving every week instead of blaming each other for breakdowns. Planning reliability is typically improved significantly with the implementation of this process focused approach to planning which involves key stakeholders including those who actually do the work.

Technology Implementation. Teams working in a Lean IPD environment are focused on process efficiency, continuous improvement and reducing waste. Technology is constantly changing and evolving, giving teams new solutions with every new project. Effective teams focus on the problems they are trying to solve first and then roll out tools to aid in their process solutions.

While technology does not replace collaboration, it helps make it more transparent, efficient, and widespread.

Conclusion

Overall, complex capital projects are very difficult. With scientific developments, they are becoming larger, more complex, and harder to control than ever before. If we continue to address the upcoming projects with the delivery methods of the past, we are doomed to repeat the outcomes we have been achieving over the last 100 years.

Lean IPD offers a new way of delivering complex capital projects with documented improved outcomes. One health system in California has delivered over $5 billion in projects using Lean IPD and so far have returned nearly 4% of overall capital and delivered 95% of projects on or ahead of schedule.

If you want different outcomes, it’s time to try something different.

You can learn more about Lean Integrated Project Delivery in this free document: Integrated Project Delivery - An Action Guide for Leaders

This post has been modified and was originally published at https://www.fieldwire.com/blog/

James is an expert in the set-up and structure of large, complex capital projects using Lean and Integrated Project Delivery to drive highly reliable results.

He has negotiated IPD contracts and delivered over $650M in complex healthcare projects as an Owner's Representative with multiparty contracts, aligned team incentives and collaborative delivery models.