How validation fixes the problem you didn’t know you had.

The construction industry hides a dirty secret. It hides this secret from the public, it hides this secret from the owner, and worst of all, it hides this secret from itself. It is a known and accepted fact that the majority of projects are delivered late, over budget, or both. So what is the secret? In the industry, even construction “successes” are usually failures!

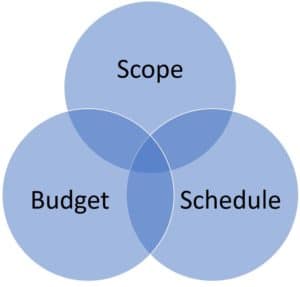

In the construction industry we say that there are three primary measures of a capital project: schedule, scope, and budget. A recent survey of owners by Dodge Analytics found that over 70% of capital projects were late, over budget, or both, meaning that only 30% of projects are on time and on budget.

In a critical oversight, but sadly not a surprising one, the owners in the survey were not asked if they had received the original scope they requested. The unfortunate truth is that even when projects are on time and on schedule, the owner often does not receive the original project scope.

This is the dirty secret of construction. We don’t measure or report how effective we were in delivering the original scope of a project. While there is a natural process of refining scope while designing a project, that is a different exercise than having to modify or eliminate scope in later design phases for the project to meet the budget. Unfortunately, this can severely impact the way an owner operates a new facility, harming their ability to turn a profit and extending the time needed to repay the capital cost of the building.

You would never see a news clip that states “the hospital was delivered on time and on budget but a wing of beds was shelled because it was the only way to get back on budgetl.” That shell space would be portrayed and sold as “growth,” when in reality, the scope is simply kicked down the road to another capital project cycle.

Fortunately, there is a solution! Lean thinking tells us that we should never begin an activity that we cannot finish. This applies to capital projects in that a project team should never begin work until the program, schedule, and estimate are set.

Far too often the design process is used to define the project, an inherently speculative (read: wasteful) process, inevitably leading to value engineering (read: scope reduction) – the key ingredient for a scope failure. A number of owners with active capital facility programs use a process called validation to avoid these pitfalls.

Taken in the lean context, a validation exercise determines the scope of a project and establishes the conditions of satisfaction that govern how the team will deliver it. This is accomplished by assembling an integrated team of stakeholders who work collaboratively to refine the program, the base design as reflected in a working estimate, a project schedule, and a pro forma that describes the target business plan and schedule for capital facility ROI.

Functionally, the team proposes alternatives that are run through a validation cycle. The owner may ask for a surgery center with four operating rooms. The designers develop a functional program and test fits that are priced and scheduled by the builder. The owner plugs the schedule and cost data into the pro forma to test payback against the business plan. The team then undertakes alternatives to improve various aspects of the cycle. One fewer operating room would cost less to build but would extend the payback while an additional operating room would cost more to build but would increase operating capital.

After multiple, rapid cycles of validation, the team settles on a best value solution that the team can deliver on time and on schedule. Most importantly, the team will deliver a facility that the owner can afford and that meets their operational objectives. Full scope, delivered on time and on budget!

The sound lean thinking in this approach is reflected by the fact that project delivery becomes a task of execution rather than one of exploration. There is no question that the team will need to work hard to deliver scope, with myriad design decisions required to achieve the conditions of satisfaction. But seeking how best to deliver on design intent is a different kind of exercise than seeking to uncover the design intent.

As lean thinking permeates the construction industry, scope must become a stated measure of success. Right now, we need owners to demand that teams accept scope accountability. Scope failure must be seen as project failure and validation is the remedy!

Romano Nickerson is a healthcare architect and principal with Boulder Associates Architects. He is a passionate advocate for Lean design and project management. Nickerson has presented at Lean Construction Institute's annual Congress, the Lean Design Forum, the Associated General Contractors of America Lean Forum, the Planetree National Convention and at local Community of Practice (CoP) meetings of LCI across the country. Nickerson serves as the LCI representative to the AGC Lean Sub-forum and co-authored a paper entitled "Production Control Principles" for the International Group for Lean Construction.