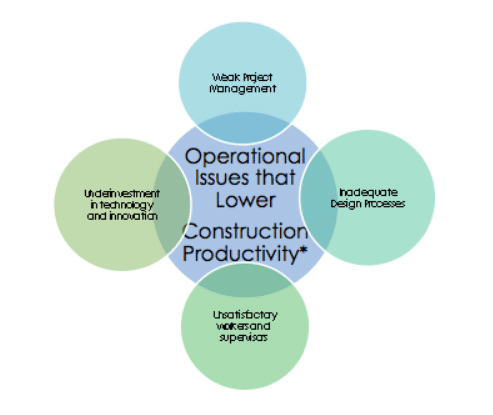

There is deep recognition in the construction industry that driving higher productivity is key to lowering project costs. While there are external forces at play, such as increasing project complexities, regulations, scope changes, labor shortages, and more, many inefficiencies and cost overages stem from internal productivity issues and resistance to change.

Source: MGI Study: Reinventing Construction: A Route to Higher Productivity

From my 20 years of experience working with U.S. and international firms to help them adopt or refine Lean IPD, I know that this methodology boosts team and project productivity.

So why do not more teams embrace Lean and IPD?

The problem is that humans are inherently resistant to change.

The roots of resistance: fear, complacency, and cynicism.

As a Lean coach, I found that the main challenge for Lean teams is to get supervisors and workers on board.

Initial and ongoing resistance takes many forms. In this article, l focus on

- Fear

- Complacency

- Cynicism

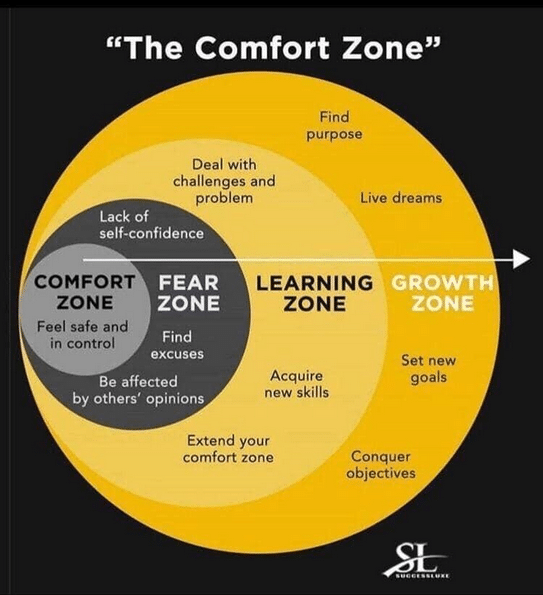

- Fear

Who wants to be out of their comfort zone? Yet, this is the only place where growth happens. Change is a pain, and often, the pain comes from deeply rooted fear of failure. It’s also inconvenient to shift from practices that have been in use for decades. Even when there’s an intellectual acceptance that the status quo isn’t working, resistance exists. People see the results of Lean Construction and IPD and say ‘I want that!’ but few have any idea what it takes to get to that state and often balk when they have a look into the process.

Image: peoplehrsolutions.com

- Complacency

You can also call it inertia. “Why fix something that’s worked for so long?” is what I often hear, even if it isn’t true. Many teams I work with have Lean practices in their ‘tool kits’ already which tempts me to go down the path of “Look, this is easy, you do a lot of it already...so hop on board and let’s get going!” That’s one way to fight resistance, but it can backfire when people voice the idea, “Since I already do this stuff, I can keep doing what I have been doing. Why do something new?” At this point, show team members how they can improve their current process. Eliminate inertia by adopting the best practices you’ll find at the end of this post.

- Cynicism

Anyone who has been in business in the last few decades has been subjected to change programs of all types, sometimes multiple times. A Harvard Business Review article on Change Management titled “Cracking the Code of Change” asserts that over 70 percent of change initiatives fail, and that failure is most often due to front-line managers not being looped into the process. Managers at every level can become cynical after failed change initiatives and may silently reject any new attempts, even while they pay the expected lip service of support. Buy-in at every level of management is essential, but for those who are closest to the workers every day, it’s critical. The easiest way to help every manager understand how the process supports success is by providing definitive proof.

Use case studies to prove your point

Nothing convinces people like success. I often use my case study Lean vs Traditional Construction, a project for the ThyssenKrupp Steel and Stainless plant in Alabama.

Two identical structures, constructed at the same time on the same site, one built with a traditional mindset of ‘go as fast as you can’ and the other with Lean thinking and tools. The results of the Lean portion speak for themselves:

- $5 million in total savings

- 19 percent faster completion

- 12 percent fewer labor hours expended

- 65 percent fewer incidents and injuries

A checklist for a successful implementation of Lean IPD

Setting the stage, providing context, case studies, and clarity all go a long way to support adoption and successful implementation. Resistance comes in many forms, and all of them can be a ‘cancer’ that eventually affects the whole team if not checked. Having worked with over 400 project teams, I have become highly skilled at spotting resistance. There is not an argument, gripe, or complaint that I have not already heard before. So when I see it, I address it immediately. I welcome the challenge and keep the dialogue open, offer guidance, and describe benefits to sway resistors to my side.

Another power that overcomes resistance is peer pressure. Many GCs and CMs mistakenly believe their 300-page contract and 10,000 line item schedule are paramount to driving action in the field. In reality, most craft leaders and workers never see the contract or schedule and could care less about either document. What they do care about is their ‘fellow soldier in the trenches.’ They don’t want to disappoint or let their peers down in any way. By using written weekly work plans and public commitments, we greatly enhance buy-in and the likelihood work will get done as planned. Peer pressure greatly enhances the other best practices listed below.

|

Removing Obstacles to Positive Change: the Lean Buy-in Checklist

|

||

|

Success begins at the top |

Have buy-in from both top and front line management at the start.

|

|

|

Set the stage |

Let people know far ahead of time that you’ll be instituting Lean and continuous improvement processes. Put the expectations in the front end documents.

|

|

|

Check your timing |

Give adequate notice of the actual start date for implementation and follow through with personal outreach.

|

|

|

Provide context |

Make sure that all staff members involved understand how the process solves problems and creates improvements that will benefit them and the company and team.

|

|

|

Start a dialogue |

Keep the conversation going and address any problems or challenges with your team every step of the way.

|

|

|

Be clear, be certain |

Enthusiasm and confidence are contagious. Be clear that this is the way things are going to be and that it’s a new day.

|

|

|

Pace properly |

Implement with the right cadence, don’t rush processes, especially at the beginning, but also don’t go too slow and lose your momentum and team enthusiasm.

|

|

|

Celebrate milestones |

When you reach goals along the way, recognize individual and team achievements.

|

|

The journey of implementation for Lean Construction and IPD is a long and arduous one, but it’s worth the effort.

Remember: address resistance immediately, use peer pressure to drive accountability, and follow the Buy-in Checklist.

Everything you want is on the other side of fear and resistance.

Further reading on change resistance

Proven Change Management Principles

David MacNeel regularly presents on Lean thinking, Lean Project Delivery, and Last Planner System® at the local and national level. His firm On Point Lean Consulting has coached hundreds of large-scale construction projects across the U.S., and internationally which resulted in significant cost and schedule savings as well as far fewer safety incidents and injuries. These projects range from hospitals to high-rise towers to theme parks and more.